The stainless steel reed, installed on the beater of your shaft loom, has two jobs:

- It spaces the warp ends evenly at the sett you want.

- It beats the weft into place as you weave each pick.

Schacht sells reeds designed to maximize the weaving width of our looms. When you're buying a reed, it's helpful to understand how it's designed.

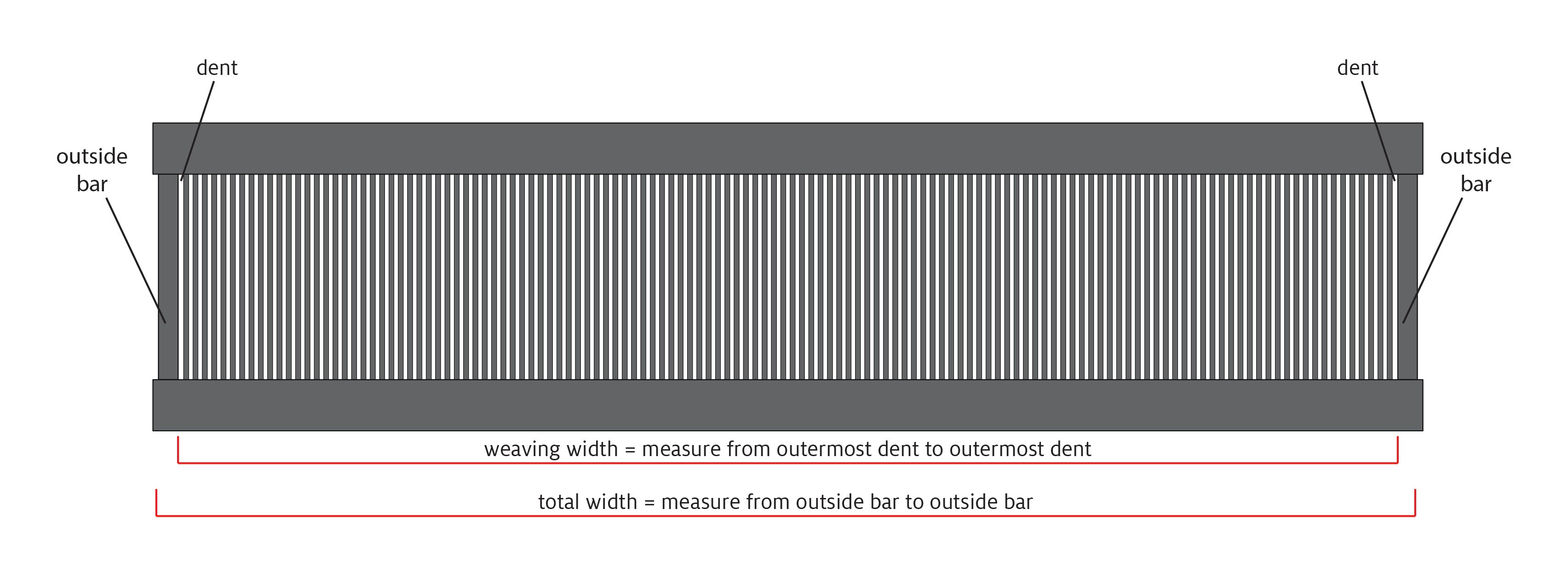

- Very narrow metal bars run vertically in the middle of the reed. They're spaced more closely or widely depending on the reed's dent—the open spaces between the bars. Warp ends go in these spaces.

- Wider outside bars close off the last dent at each side of the reed. There are also bars along the top and bottom edges of the reed to hold the warp ends in the dents.

- Stainless steel reeds do not have a top or bottom, front or back.

To determine the reed's dent, measure 1" with a ruler and count the dents. The reed's dent is also stamped on one of the outside bars.

A reed has to fit in your loom's beater. Measure the reed's total width to figure out if it will fit between the beater sides. (A reed's height and thickness will almost never matter. On most looms, the beater's top and bottom have big grooves to hold the reed. You can raise or lower the beater top to hold the reed snugly.)

The measurement between the two outside bars is your reed’s weaving width. When you warp the loom, you can fill each dent to weave full width.

You can use any reed that will fit into the beater, even if the reed doesn't fill the width of the beater, but you'll sacrifice some of your loom's weaving width. For example, the Cricket Quartet has a weaving width of 13-1/2" and our smallest Table Loom has a weaving width of 15". If you use a Cricket Quartet reed on that Table Loom, you're limited to the reed's weaving width.