Natural Dyeing, Part 2: Summer Sunset Table Runner

Designed and woven by Sienna Bosch

Weaving with hand-dyed yarn makes for never-ending surprises—I never know what the next pick will bring, so the sense of ambiguity keeps me on my toes. Joining forces on a piece brings the same mystery and excitement. Caroline Worrell hand-dyed a gorgeous warp, which sparked our collaboration. This project brought these two worlds into one.

Much of my work combines natural dyes and weaving. This project, however, brought me out my comfort zone. It was an entirely different way of working with naturally dyed yarns, inspiring me to see where else this combination could take me. The dye painting process brings out color variations in a whole new way: you can see the transition between colors vividly. Each and every strand of yarn has its own character.

After Caroline dropped off the hand-dyed warp, I started experimenting for a table runner 14" wide. I began playing with patterns to see what I was drawn to. But I noticed that the beautiful naturally dyed colors weren’t being highlighted, no matter what pattern I used. They were fading to the background as the warp and weft interlaced. It was time to change my sett.

I re-threaded my reed going from 20 EPI to 40 EPI, which cut the weaving width in half. Suddenly the colors popped, and I knew I was headed in the right direction. I explored several patterns, but landed on plain weave. This simple structure accentuated the beauty of the naturally dyed warp. I added in a few picks of leno at each end of the runner to add interest.

As with the close of every project, I’m feeling inspired to continue exploring the endless possibilities of weaving. I encourage you to try something new along with me. Happy weaving!

Project Specs

Weave structure: Warp-faced plain weave and leno

Finished size: 33" x 7"

Total Warp Ends: 280

Warp Length: 2 yds, including take-up and loom waste. Caroline wound and dyed 4 yds to make sure there was room for sampling; if you want to make a longer runner, dye more yarn and weave more than 29" plain weave in the center section.

Width in Reed: 7"

EPI: 40

PPI: 15

What You'll Need

-

Hand-dyed unmercerized 8/2 cotton; 560 yds for warp, 250 yds for weft

-

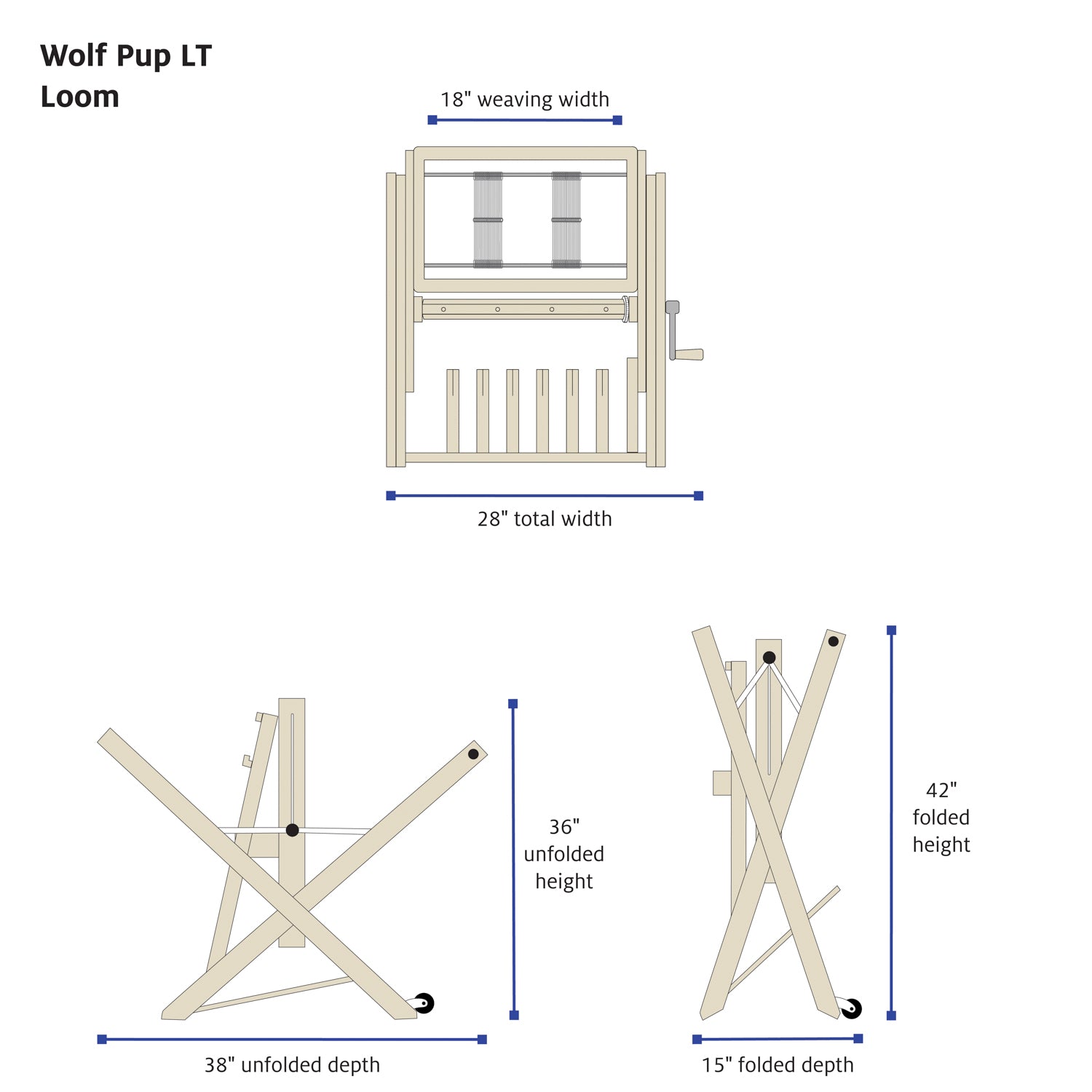

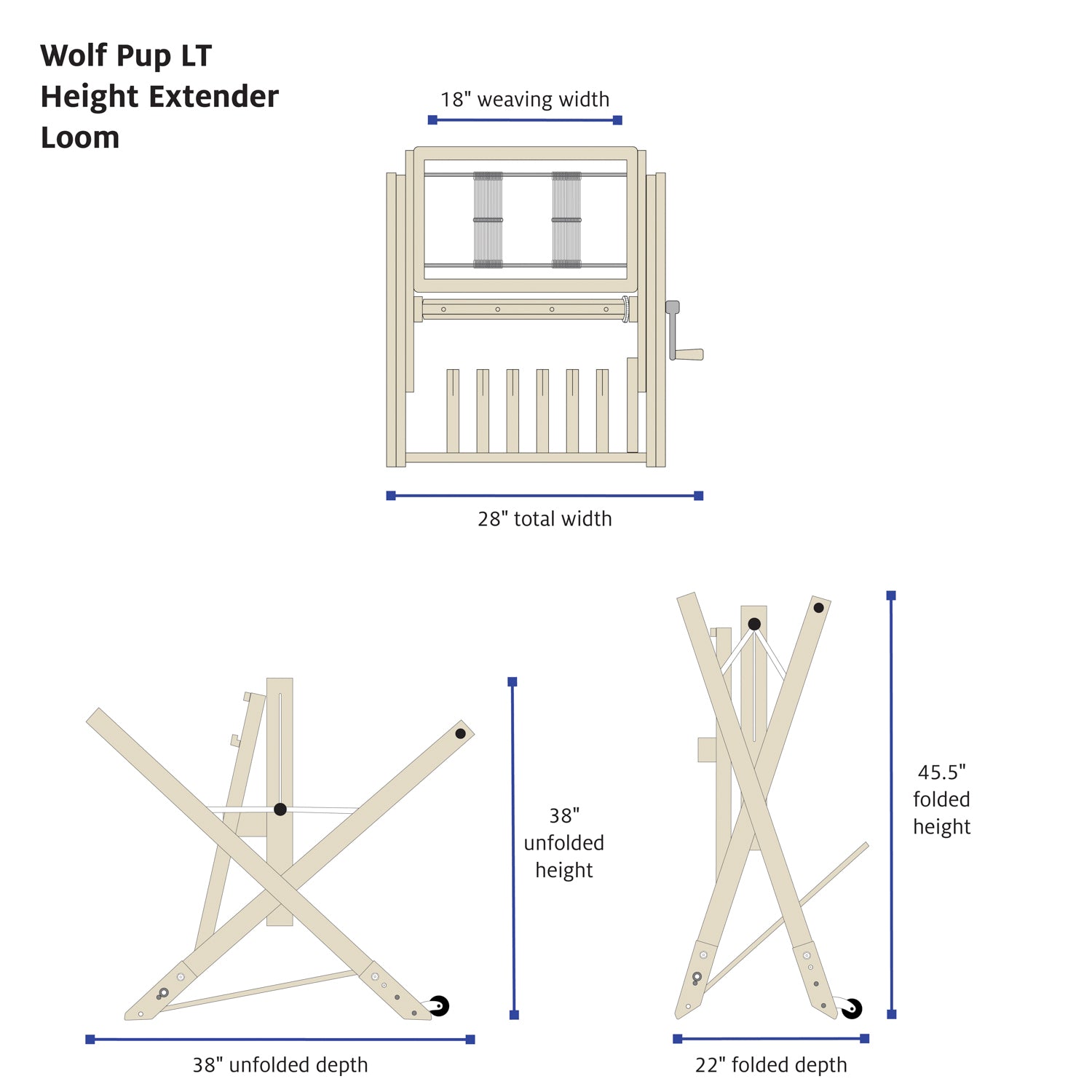

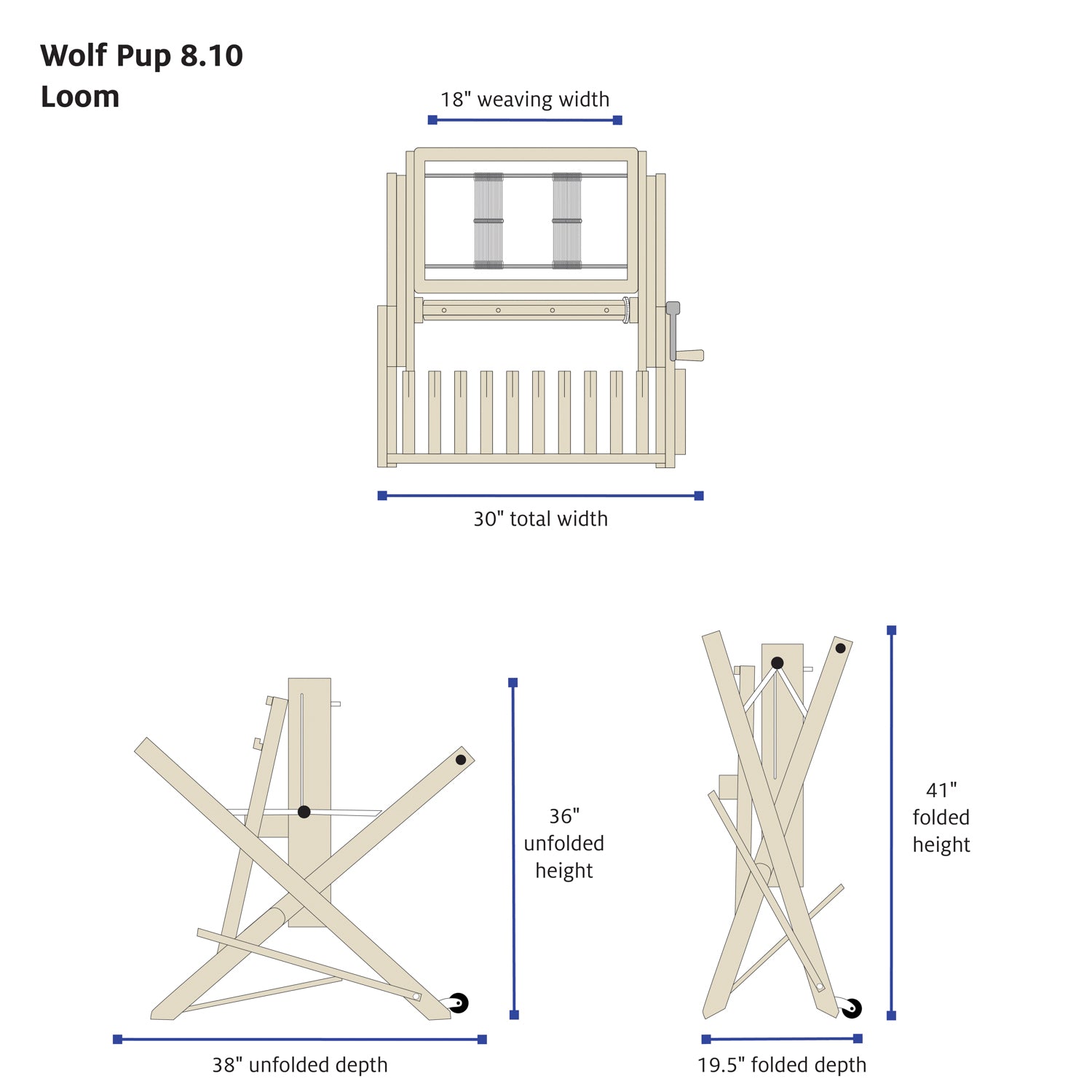

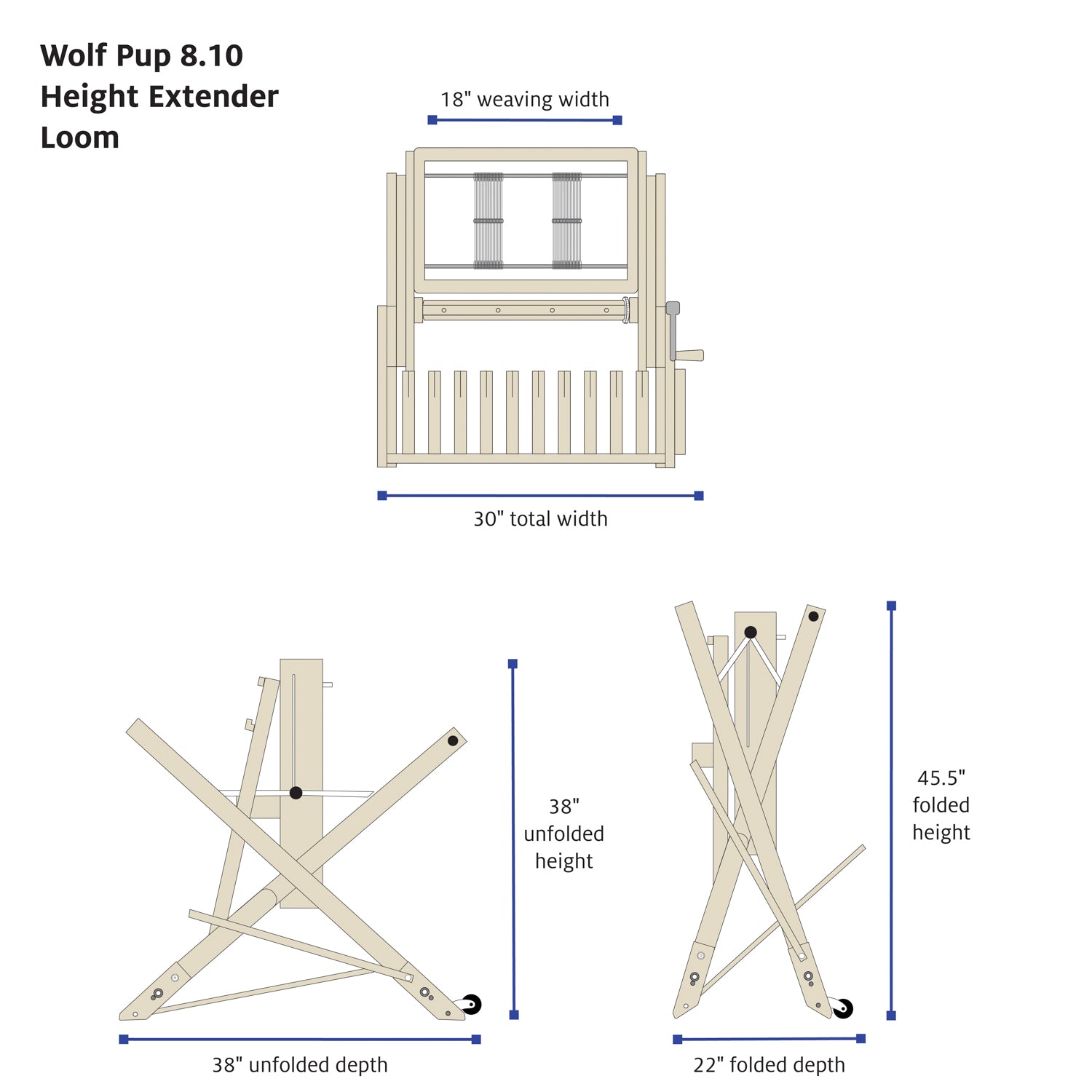

4+ shaft loom with at least 18" weaving width and a 10 dent or 20 dent reed—I used my 8-shaft Mighty Wolf

-

pick-up stick at least 10" long

-

tapestry needle for hemstitching

-

scissors or rotary cutter and cutting mat

Materials

Equipment

Directions

Warping

- Thread the reed at 40 EPI. I used a 10 dent reed with 4 ends per dent. You could also put 2 ends per dent in a 20 dent reed.

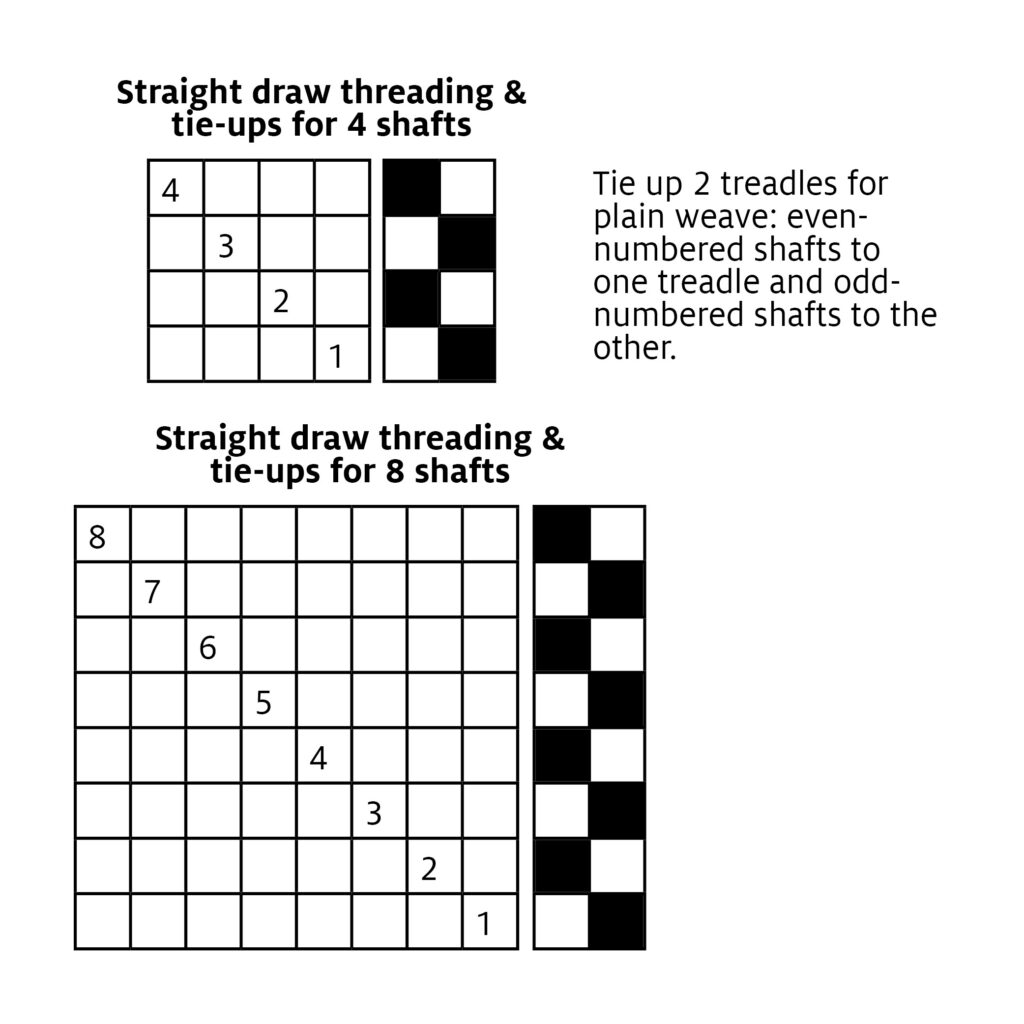

- Thread the heddles with a straight draw, using as many shafts as your loom has. While this design is not entirely warp-faced, the warp is more dense that the weft. Weaving will be much easier with more shafts because the heddles won't be packed together.

Weaving

Spread the warp with a header. Leave a 1-1/2" gap between the header and the start of the weaving to form the fringe.

- Leave a weft tail on your dominant hand side (right side if you are right-handed) that is 4 times the width of the weaving for hemstitching.

Work plain weave for 11 picks. Hemstitch in groups of 4 warp threads and 2 weft threads.

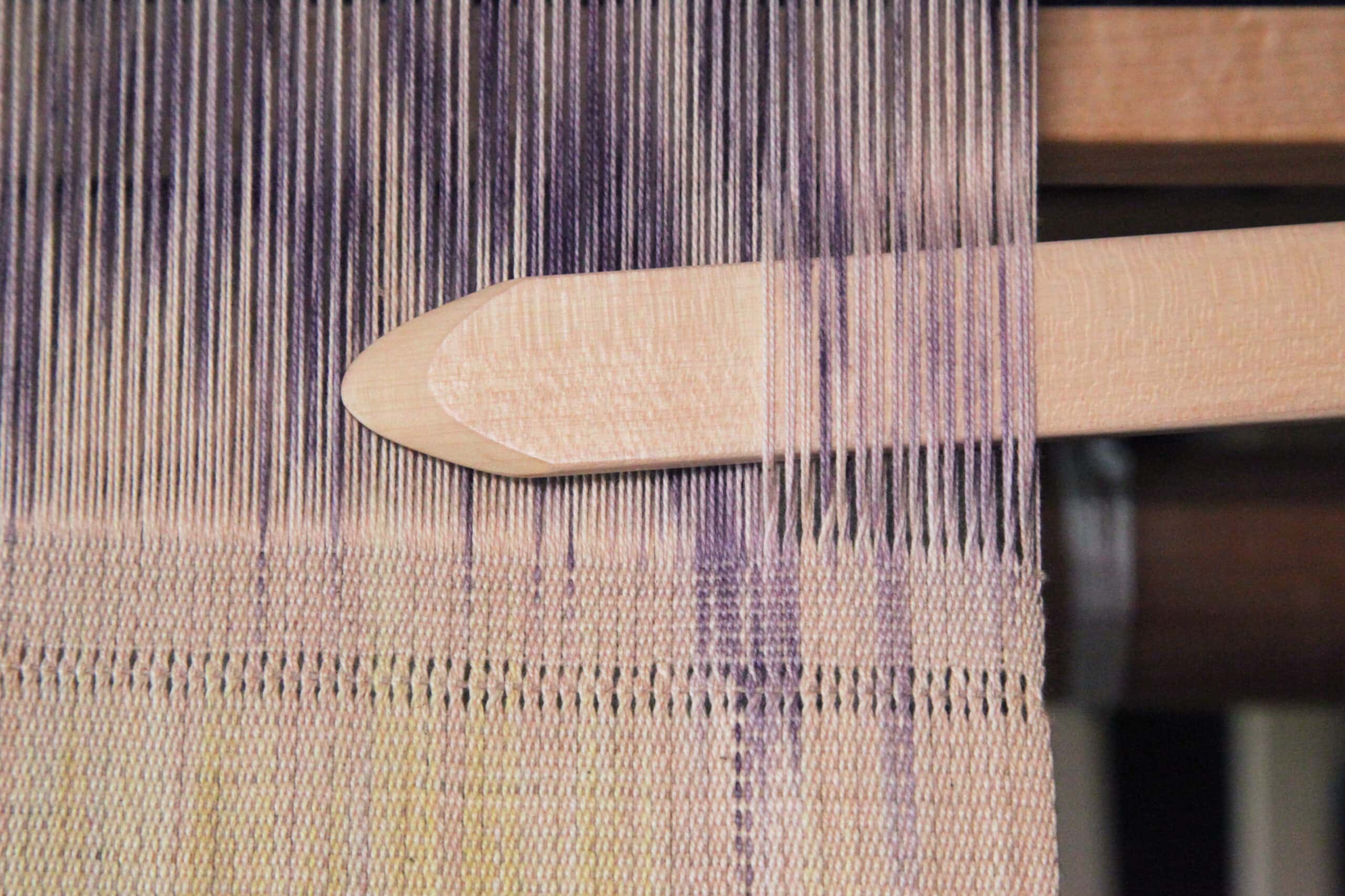

Work leno: Open the next shed. Use a pick-up stick to go over the first 2 warp threads on the upper set of threads. Bring the pick-up stick down to the lower set of threads, picking up the first 2 threads. You will see a twist form in the threads.

Place your pick-up stick over the next 2 upper threads, then under the next 2 lower threads. Repeat across the entire warp.

Place the pick-up stick on edge and place the shuttle through the shed you just created. Remove the pick-up stick and beat the pick. When you open the next shed, the warp threads will untwist.

Continue weaving: Work plain weave for 11 picks. Weave 1 pick of leno.

Weave 29" in plain weave. Weave 1 pick of leno.

Work plain weave for 11 picks. Weave 1 pick of leno. Work plain weave for 11 picks.

Leave a weft tail 4 times the width of your weaving. Hemstitch in groups of 4 warp threads and 2 weft threads.

Finishing

- Cut the weaving off the loom, leaving a few inches of warp at the end.

- Cut fringe at each end, 1" from the hemstitching, using scissors or a rotary cutter and cutting mat.

Hand wash your weaving with a mild laundry detergent. Lay flat or hang to dry. Cut off any weft tails.

Display your table runner on any table in your home—it will add a colorful touch to any surface.

Notes

- In warp-faced weavings, spreading the warp is more difficult than other structures. Press the treadle down and use your hand to open the first shed. You may need to do this several times before the shed opens cleanly.

- When the warp threads twist back after a leno pick, the shed may be difficult to open. Use your hand to open the shed cleanly.